Make A list

Make a list of the appliances and motors that must run during an electrical power failure. It is suggested for Stand-by service that you include only essential equipment.

2. Calculate Your Wattage

When you have completed the list enter the number of watts required to operate each item. the watts required for operation are usually stamped on the nameplate of the product.

If only the ampere rating appears on the Product, Multiply the amps by the voltage to obtain the Wattage.

1000 Watts Equals 1KW.

Remember that electric motors require more power when starting then when running. Starting one Motor at a time, Beginning with the largest down to the smallest, will reduce the size of the alternator you need.

3. Choose your Generators

Some motors require more starting current then others, and all require more starting current than running current.

Split-phase motors are more difficult to start and require 5 to 10 times as much current compared to running current.

Motors with capacitor start require 2 to 4 times as much current to start compared to running current and is dependent on the NEMA Code letter Rating.

Repulsion Induction Motors require 1.5 to 2.5 times as much current to start compared to running current.

Determine your largest motor starting requirement by the HP rating and the NEMA code letter on the Nameplate.

Refer to the tables below for the approximate wattage per HP by NEMA Code Letter. For the Total Starting Wattage Required, Multiply this Figure by HP size of your Motor

Need help with your Calculations, and Choosing your Generator Type?

NEMA Code Letter & Wattage

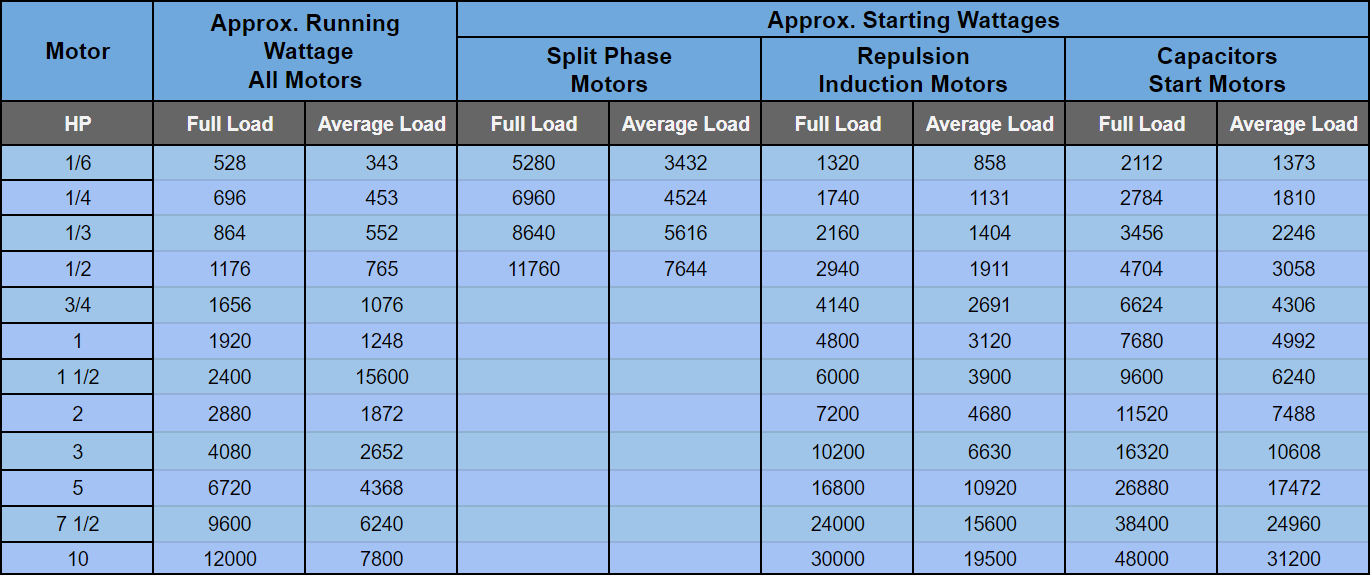

Approximate Wattage Consumption of running and starting electric motors

Approximate Running & Starting Wattage of all Motors

Total all Requirements, and add approximately 25% for overlooked items and miscalculations. Select an alternator that is equal to or greater than the rated output requirement of you load. Never pick an alternator smaller then your load requirement, as damage can be done to the alternator by continuously overloading it.

Approximate Wattage Consumption of running appliances